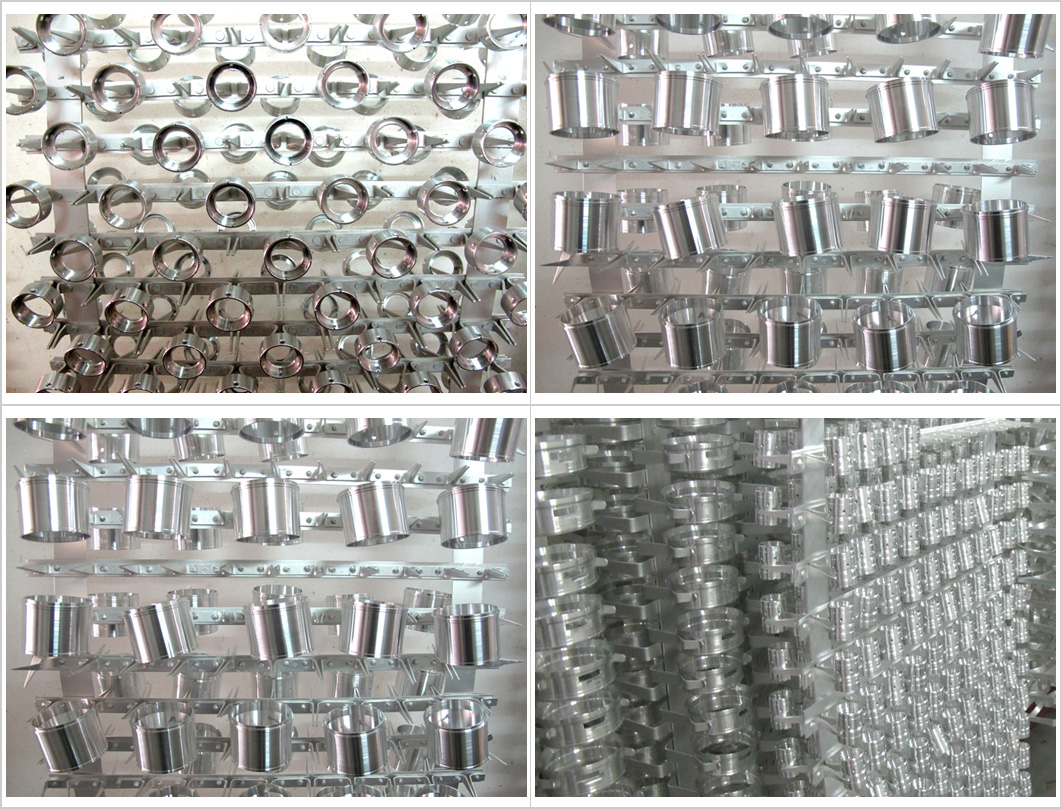

Turning and Milling black anodized parts

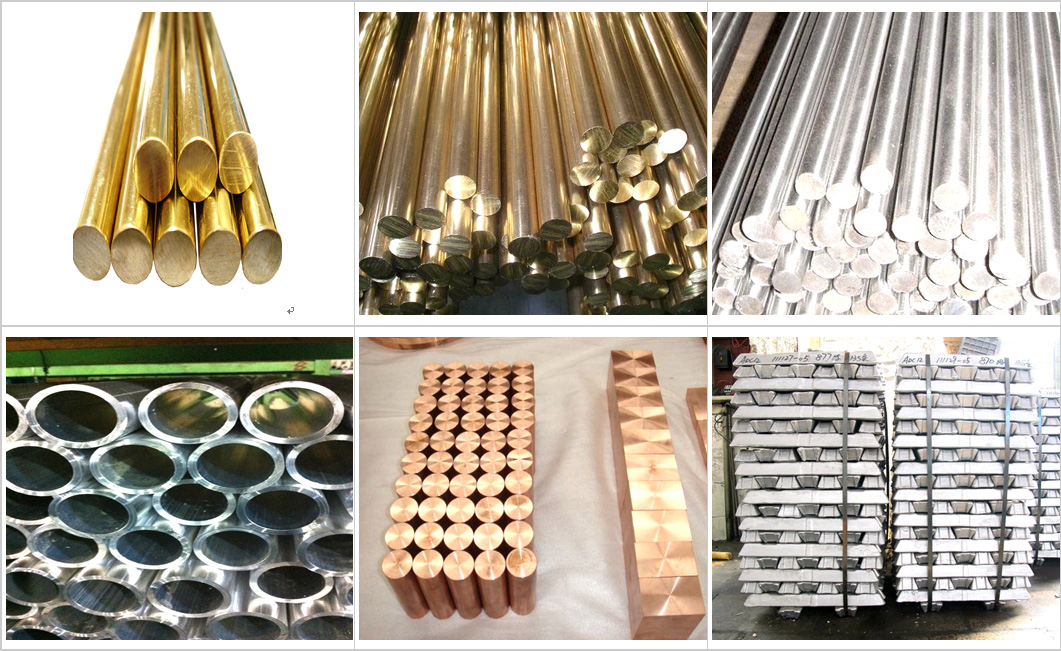

Brass material parts

The anodized parts such like the black or other color, it should be fixed on the tooling (refer to the following pic.)before anodized, then put into the water cleaning and to do the anodizing with the other around 9 different jar. All the surface treatment processing can meet the ROHS requirement, and we have passed SONY GREEN PARTNER certification.

| Stainless steel

|

300series | SUS303,SUS304,SUS304L,

SUS316,SUS316L ,SUS317,SUS317L |

| 400series | SUS420J2,SUS430,SUS434 | |

| 600series | SUS630 | |

| Steel

|

Carbon steel | S10C,S20C,S30C,S45C,S50C |

| Cr-MO | SCM415,SCM435,SCM440 | |

| Ni-Cr-MO | SNCM415 | |

| Special steel | K,SUJ1,2,3,…,SK(1,2,3,…) | |

| Aluminum | – | A2011,A2017,A5052,A5056,A6061,

A6063,A7075 |

| Cu | – | C3600,C3604 |

|

Feature:

1,Material:A5056 pipe or Japanese semi-product 5,measuring:check the curve groove direct,groove position ±3′ |

|

Feature:

1,Material:Chinese A5056 pipe; |